Something is quietly shifting in Maryland’s industrial landscape. After decades of outsourcing, manufacturing is showing signs of coming home, and precision technology is at the center of this movement. Fiber laser cutting, in particular, is reshaping how manufacturers in the state think about production: faster turnaround, pinpoint accuracy, and leaner costs.

As businesses seek to reduce supply chain risks and meet tight timelines, advanced fabrication methods like laser cutting are playing a pivotal role. From custom parts to large-scale production, fiber lasers are unlocking new efficiencies that manual and mechanical methods can’t match.

This article will walk you through how metal laser cutting works, which materials are compatible, the economics of the process, and how Maryland-based manufacturers are using it to strengthen local production and competitiveness.

Can Metal Be Cut with a Laser?

Yes, and today it’s done with remarkable speed and accuracy. Laser cutting metal involves focusing a highly concentrated beam of light to heat, melt, or vaporize the material at the point of contact. What once required mechanical sawing or abrasive cutting can now be completed in seconds—with no physical contact and minimal tool wear.

Traditional methods like shearing and drilling introduced limitations in terms of geometry and finish quality. In contrast, modern laser systems offer cleaner edges, tighter tolerances, and far more design freedom. As the technology matured, businesses began replacing outdated mechanical systems with high-performance lasers capable of cutting stainless steel, aluminum, and other challenging metals effortlessly.

How Does Metal Laser Cutting Work?

Metal laser cutting is a multi-step process that transforms digital designs into real-world parts with micron-level precision. Here’s how the typical workflow unfolds:

- CAD design preparation

- Machine setup and material loading

- Laser beam generation

- Beam focusing and guidance

- Material vaporization or melting

- Assist gas application (O?, N?, air)

- Cut completion and part removal

Each step plays a crucial role in delivering consistent, high-quality cuts. The use of assist gases like oxygen or nitrogen enhances the cutting process by speeding up oxidation or preventing metal discoloration, depending on the material.

What Are the Different Types of Laser Cutters Used for Metal Cutting?

Different laser systems are engineered for different tasks. Here’s how the main types compare in the context of metal cutting:

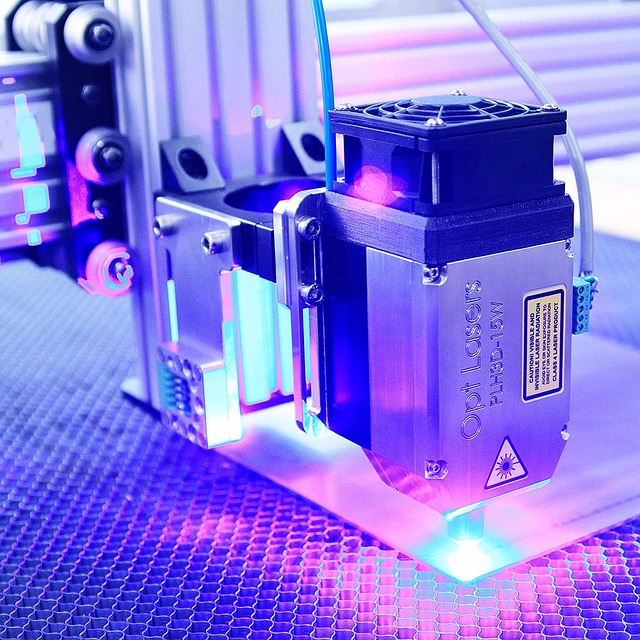

Fiber Laser Cutters

Fiber laser cutters are solid-state machines that use fiber-optic cables to deliver a highly focused beam. They are exceptionally efficient when working with reflective metals like aluminum and copper. Thanks to their minimal maintenance and high electrical efficiency, fiber lasers have become the standard in modern metalworking shops.

CO? Laser Cutters

CO? lasers use gas excitation to produce a laser beam. While effective on thick materials and non-metals like wood or plastic, they’re less efficient for cutting metal. They require more maintenance and higher power input to match the performance of a fiber system.

Crystal (YAG) Laser Cutters

Crystal lasers offer high peak powers, making them suitable for engraving or cutting thin metals. However, they come with a higher upfront cost and have shorter lifespans compared to fiber lasers, making them less practical for high-volume production.

What Are the Main Parts of a Metal Laser Cutter?

Each metal laser cutter is a complex assembly of systems working in harmony. Key components include:

- Laser resonator (source)

- Beam delivery system

- Cutting head with focusing lens

- Assist gas nozzles

- Motion system (gantry, motors)

- CNC controller

- Cooling system

- Exhaust and filtration system

Every part contributes to cut quality, repeatability, and operational safety.

What Are the Main Parameters of Laser Cutting Metal?

Precise control over these parameters determines the success of every cut:

- Laser power (watts)

- Cutting speed

- Material thickness

- Assist gas type and pressure

- Focal length

- Kerf width

- Pulse rate (for pulsed lasers)

What Are the Cutting Tolerances for Metal Laser Cutting?

Accuracy depends on both machine capability and material. Typical tolerances include:

- Thin sheets (?1mm): ±0.1mm to ±0.2mm

- Medium thickness (1–5mm): ±0.2mm to ±0.5mm

- Thick metals (>5mm): ±0.5mm to ±1.0mm

What Is the Thickest Metal That Can Be Laser Cut?

Fiber lasers can handle a surprising range of thicknesses:

- Mild Steel: up to 25mm (?1 inch)

- Stainless Steel: up to 20mm (?0.8 inch)

- Aluminum: up to 15mm (?0.6 inch)

What Are Metal Types Suitable for Laser Cutting?

Each metal brings its own characteristics to the table. Below are key insights:

Mild Steel (Carbon Steel)

- Low reflectivity

- Moderate thermal conductivity

- Good edge quality

- Cost-effective for structural parts

Stainless Steel

- High corrosion resistance

- Clean cutting with nitrogen assist gas

- Smooth finish with minimal dross

Aluminum

- High reflectivity

- Requires high-power lasers

- Good strength-to-weight ratio

Brass

- Reflective and conductive

- Prone to burrs

- Suitable for decorative applications

Copper

- Highly reflective

- Excellent electrical conductivity

- Requires precise control to avoid burn-through

Galvanized Steel

- Zinc coating produces vapor during cutting

- Proper ventilation is essential

Titanium

- Strong and lightweight

- Demands inert gas shielding to prevent oxidation

Nickel Alloys

- Hard to cut mechanically

- Laser cutting maintains accuracy on tough metals

Silver

- High reflectivity

- Often cut for jewelry or electronics

Gold

- Expensive material, requires clean, efficient cuts

Platinum

- Used in medical and luxury sectors

- Requires high precision

Zinc

- Low melting point

- Careful control needed to avoid warping

Tin

- Soft metal, limited structural use

- Clean finish with low laser power

Lead

- Toxic fumes require strict fume extraction

- Limited use cases

Inconel

- Extremely strong under heat

- Common in aerospace and defense

What Is the Best Metal for Laser Cutting?

Mild steel often wins on affordability and versatility. Stainless steel is a close second for applications requiring durability and corrosion resistance. Ultimately, the “best” metal depends on the desired balance of cost, cut quality, and machine compatibility.

What Are the Advantages of Using Laser Cutting to Cut Metals?

Laser cutting delivers a host of advantages that make it ideal for modern metalworking:

- High cutting speed

- Exceptional precision

- Minimal material waste

- Clean, burr-free edges

- Works on reflective metals

- Automation-friendly

- No need for tooling

- Low setup time

- Consistency in mass production

What Are the Industries That Utilize Laser Cutting for Metal?

Metal laser cutting is not limited to one sector. It supports a wide array of industries where precision and efficiency are paramount:

- Aerospace – aircraft brackets, precision housings

- Automotive – chassis parts, gears

- Medical – surgical instruments, stents

- Construction – structural components

- Electronics – enclosures, heat sinks

- Jewelry – custom shapes in precious metals

- Agriculture – plow blades, fittings

- Renewable Energy – solar panel frames, turbine parts

What Are Important Factors to Consider When Laser Cutting Metal?

Proper planning is essential for safe and accurate results. Here are critical factors to account for:

- Material thickness and type

- Edge quality requirements

- Kerf width and tolerances

- Thermal conductivity

- Reflectivity of the metal

- Assist gas choice

- Safety protocols

Common mistakes that reduce cut quality or increase risks include:

- Incorrect focus settings

- Insufficient gas pressure

- Ignoring kerf compensation in design

- Overlooking ventilation

How to Laser Cut Metals?

The process, while technical, can be streamlined by following these steps:

- Choose the right machine and material

- Prepare and optimize the CAD file

- Load material onto bed

- Set focus height and laser parameters

- Initiate cut with proper assist gas

- Inspect finished cut

- Remove parts and perform post-processing

Safety Tips When Metal Laser Cutting

Safety must be built into every job:

- Wear protective eyewear

- Use proper exhaust systems

- Keep flammable materials away

- Check for reflective surfaces

- Ensure machine interlocks are functioning

Design Tips for Metal Laser Cutting

Good design reduces risk and waste:

- Avoid sharp internal corners

- Allow for kerf in slot/tab fits

- Use consistent line weights in CAD

- Minimize intricate detail on thick materials

- Label parts directly in the design

Which Are the Best Metal Laser Cutting Machines?

When choosing the right system, consider:

- Power output and speed

- Cutting area size

- Ease of use and automation options

- Cooling and ventilation system

- Software compatibility

- Brand reliability and support

- Maintenance cost and frequency

What Are Alternative Technologies and Processes Used for Laser Cutting Metal?

Depending on the job, other cutting technologies may be used:

- Plasma cutting – faster for thick metals, less precise

- Waterjet cutting – no heat-affected zone, but slower and costlier

- EDM (Electrical Discharge Machining) – precise, but only for conductive materials

- Oxy-fuel cutting – low-cost, only works on thick carbon steel

- Mechanical shearing or punching – fast and cost-effective for simple shapes

How Fiber Laser Cutting Can Help Reshore Manufacturing to Maryland

Reshoring manufacturing is about more than just location—it’s about performance, flexibility, and cost control. Fiber laser cutting directly supports these goals.

With its ability to produce custom, high-precision parts on demand, fiber laser technology reduces the need for overseas sourcing and dramatically shortens lead times. Maryland manufacturers are increasingly leveraging these benefits to build agile, local production models.

Key reshoring advantages specific to Maryland include:

- Access to local ports and logistics hubs

- Reduced supply chain risks

- Support from state-level reshoring incentives

- Growing skilled labor force in the Baltimore–DC corridor

- Environmental and compliance advantages

By integrating laser systems into their production workflows, Maryland-based companies are turning cost centers into competitive edges.

Conclusion

In a world where time, quality, and reliability define competitive success, fiber laser cutting stands out as a transformative technology. For Maryland, it’s more than a tool—it’s a strategic enabler of manufacturing independence.

By bringing production closer to end users, reducing waste, and accelerating speed to market, laser cutting is laying the groundwork for a more resilient industrial economy. It’s not just about reshoring—it’s about redefining what’s possible when high-tech tools meet local opportunity.

Recent Comments